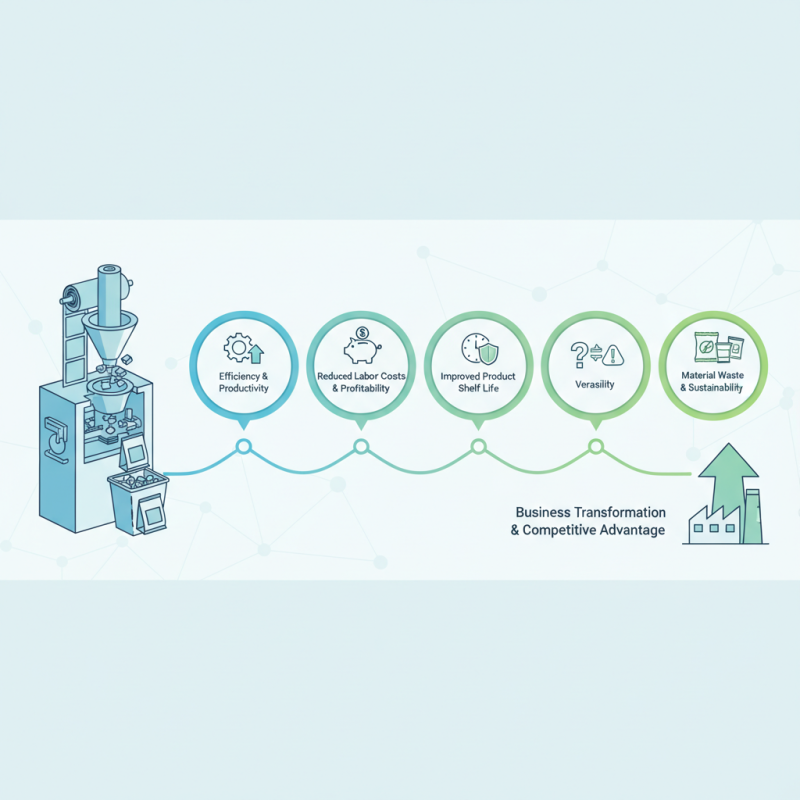

In today's fast-paced and competitive market, businesses are continuously seeking innovative solutions to enhance their efficiency and productivity. One such solution that has gained significant traction is the VFFS packaging machine, which stands for Vertical Form Fill Seal. This technology offers a multitude of advantages that can simplify the packaging process, reduce labor costs, and improve product shelf life. By automating packaging procedures, the VFFS packaging machine not only streamlines operations but also allows companies to focus more on core business activities, ultimately leading to greater profitability.

The versatility of the VFFS packaging machine further enhances its appeal, as it can accommodate various products ranging from snacks to powders, ensuring that businesses can adapt to changing market demands. Moreover, the precision and speed of this packaging solution significantly reduce material waste and contribute to a more sustainable approach to packaging. As we delve deeper into the top five benefits of using a VFFS packaging machine, we will uncover how this advanced technology can transform your business operations, empower you to stay ahead of the competition, and cater to the increasing consumer expectations for efficiency and sustainability in product packaging.

A Vertical Form Fill Seal (VFFS) packaging machine is an automated device designed to produce bags from a roll of film, fill them with a specific product, and seal them, all in one continuous process. This type of machine operates by vertically feeding the film downwards, where it is then formed into a specific bag shape. The machine utilizes heat to seal the edges of the film, ensuring that the contents are securely packaged. The versatility of VFFS machines allows them to accommodate a wide range of products, from powders and granules to liquids and solid items.

The operational efficiency of VFFS machines makes them a preferred choice for many businesses. First, they streamline the packaging process, reducing labor costs while increasing production speed. The automation minimizes human intervention, which not only enhances consistency in packaging but also decreases the likelihood of errors. Moreover, advanced VFFS machines come equipped with technology that allows for precise filling, ensuring that each bag contains the exact amount of product. This capability not only improves product quality but also optimizes material usage, thus contributing to a more sustainable production process. Overall, the integration of a VFFS packaging machine can significantly enhance a business's packaging operations, leading to increased efficiency and profitability.

When it comes to packaging solutions, VFFS (Vertical Form Fill Seal) machines stand out for their remarkable ability to enhance packaging speed and efficiency. These machines streamline the entire process, allowing businesses to package products at a much faster rate compared to traditional methods. This increased speed can significantly boost productivity, enabling companies to fulfill larger orders in shorter timeframes while minimizing manual labor.

To maximize the benefits of VFFS machines, implementing a few practical tips can be advantageous. First, regularly maintain and calibrate your machine to ensure it operates at optimal speed and accuracy. Second, train your staff on the nuances of the equipment to avoid downtime and ensure a smooth workflow. Finally, consider utilizing smart technology solutions that can predict maintenance needs and automate settings, further enhancing efficiency.

Incorporating VFFS machines into your production line not only speeds up the packaging process but also improves overall efficiency, allowing for better use of resources. By optimizing this critical aspect of business operations, companies can enhance their competitiveness and responsiveness to market demands.

Utilizing a Vertical Form-Fill-Seal (VFFS) packaging machine can significantly enhance cost efficiency for businesses operating in the packaging sector. According to a report from MarketsandMarkets, the global VFFS packaging market is projected to grow from $3.01 billion in 2021 to $4.15 billion by 2026, demonstrating an increasing shift toward automation in packaging processes. One of the primary cost savings associated with VFFS technology is its ability to minimize labor costs. With automation, businesses can reduce the number of personnel required for packing operations, which in turn lowers overall wage expenses.

Additionally, VFFS packaging machines are known for their high-speed operation, allowing companies to produce more packages in less time. A study by Grand View Research indicates that the efficiency of packaging machines has increased by approximately 20% in the past decade. This rise in efficiency means that businesses can handle larger production volumes without needing to invest heavily in additional equipment or workforce, leading to lower per-unit packaging costs. Furthermore, the precision of VFFS technology contributes to minimizing material waste, as these machines are designed to optimize the use of film and materials, propagating further savings and enhancing profit margins.

Vertical Form-Fill-Seal (VFFS) packaging machines offer businesses a robust solution for enhancing product protection and extending shelf life. One of the primary advantages of using VFFS technology is its ability to create airtight packaging that minimizes exposure to external elements such as moisture, oxygen, and contaminants. This is particularly crucial for perishable goods like food items, where maintaining freshness and quality is essential. The precision of VFFS machines ensures that each package is sealed tightly, effectively reducing the risk of spoilage and retaining the product's original flavor and nutritional value.

In addition to physical protection, VFFS solutions can significantly contribute to prolonging shelf life through custom packaging designs and materials. Businesses can select films and barriers that are specifically formulated to provide optimal preservation for different types of products, whether they are dry goods, snacks, or liquids. Furthermore, the consistent, high-speed operation of VFFS machines not only helps in maintaining product integrity during packaging but also reduces waste caused by faulty seals or ineffective packaging. This efficiency means that companies can confidently present their products to consumers with the assurance that their items will remain fresh longer, ultimately leading to higher customer satisfaction and loyalty.

Vertical Form Fill Seal (VFFS) machines have become a staple in various industries due to their remarkable versatility in handling a wide array of products. Whether you're packaging granules, liquids, or even delicate items, VFFS technology adapts easily to meet diverse requirements. This adaptability makes VFFS machines ideal not only for food packaging but also for pharmaceuticals, cosmetics, and agricultural products. Their ability to accommodate different materials and shapes enables businesses to explore new markets without a hefty investment in new equipment.

When choosing a VFFS machine, consider the types of products you'll be packaging. For instance, you might need a machine with specific features, such as a liquid filling nozzle for soups or sauces, or a gentle handling system for fragile items like snacks or baked goods. Tailoring your equipment to your specific needs can significantly improve efficiency and reduce product waste.

Tips for integrating VFFS machines into your operations include conducting thorough research on the varying types of machines available and their compatibility with your product. Additionally, investing in staff training can maximize the effectiveness of the machine and ensure a smooth workflow. Regular maintenance schedules are essential to keep your VFFS machines running at optimal performance and to prevent costly downtimes.

| Benefit | Description | Applicable Industries |

|---|---|---|

| Increased Efficiency | VFFS machines automate the packaging process, reducing labor time and increasing output. | Food & Beverage, Pharmaceuticals |

| Versatility | Capable of packaging a wide variety of products, including solids, powders, and liquids. | Consumer Goods, Chemicals |

| Cost-Effectiveness | Reduces packaging costs through efficient material usage and less waste. | Retail, E-commerce |

| Improved Product Integrity | Provides better seals and protection, ensuring product freshness and quality. | Food Processing, Healthcare |

| Customizable Designs | Allows for tailored packaging formats, sizes, and graphics to enhance brand visibility. | Cosmetics, Pet Products |