In the rapidly evolving landscape of industrial operations, the role of automation machinery has become increasingly pivotal. As industries strive for greater efficiency and productivity, innovations within this sector are redefining the benchmarks of performance. Renowned expert in automation technology, Dr. Emily Chen, emphasizes the significance of these advancements, stating, “Automation machinery is not just a tool; it is the backbone of modern manufacturing, driving both efficiency and innovation in ways we have yet to fully realize.”

As we approach 2025, the top five automation machinery innovations are set to transform the way industries operate, offering unprecedented improvements in efficiency and productivity. These innovations are not merely upgrades; they represent a fundamental shift in how businesses can leverage technology to streamline processes, reduce waste, and enhance overall operational effectiveness. With insights from industry leaders and cutting-edge research, we will explore these groundbreaking developments that promise to shape the future of industrial efficiency.

This exploration is more than just an analysis of new tools; it is a glimpse into a future where automation machinery enhances every facet of industrial operations, making businesses more competitive and responsive to market demands. As we delve into the specifics of these innovations, we aim to provide a comprehensive understanding of their transformative potential and the implications they hold for the industry at large.

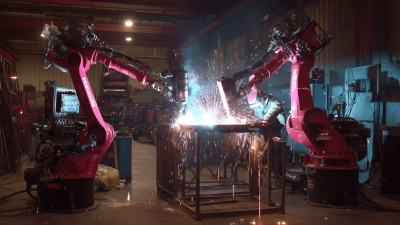

The manufacturing landscape is undergoing a significant transformation as AI-driven robotics emerge as a cornerstone in boosting production efficiency. According to a McKinsey report, companies that integrate AI in their processes could see productivity enhancements of up to 40% by 2025. These intelligent systems are capable of learning from data patterns and adjusting their operations in real-time, drastically reducing downtime and increasing output rates. This shift not only optimizes resource allocation but also enhances overall product quality.

Embracing AI-driven robotics in your production line can vastly improve operational effectiveness. One key tip is to invest in integrating machine learning algorithms that analyze workflows. This will enable your systems to predict potential bottlenecks before they occur, facilitating smoother production cycles. Additionally, training staff to collaborate effectively with these AI systems is crucial. Empowering your workforce with the skills to work alongside advanced technologies ensures maximum benefit from these innovations.

Furthermore, industry reports suggest that manufacturers who leverage smart robotics can expect a reduction in labor costs by up to 30%. This significant reduction allows businesses to reallocate resources more effectively, focusing on innovation and growth. By strategically harnessing AI-driven solutions, firms can navigate the challenges of modern production demands while remaining competitive in an ever-evolving market.

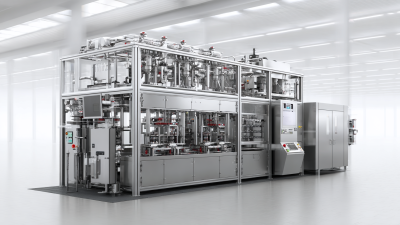

As the U.S. focuses on nearshoring and reshoring manufacturing operations, automation and robotics are becoming integral to enhancing supply chain efficiency. Automated inventory management systems are particularly crucial, as they streamline operations, reduce human error, and allow for better data insight. According to industry reports, the global healthcare supply chain management market is projected to grow significantly, with an estimated value of USD 3.95 billion in 2025, expected to reach approximately USD 6.32 billion by 2034. This growth emphasizes the rising demand for efficient supply chain solutions driven by automation.

The adoption of automated inventory management systems not only optimizes stock levels but also improves responsiveness to market changes. By leveraging advanced technologies, organizations can achieve greater visibility and control over their inventory, thereby minimizing waste and ensuring timely deliveries. With these systems in place, companies can better navigate the complexities of modern supply chains, particularly in the healthcare sector, where ensuring the availability of critical medical supplies is paramount. As automation continues to evolve, its transformative impact on industrial efficiency will undoubtedly shape the future of supply chain management.

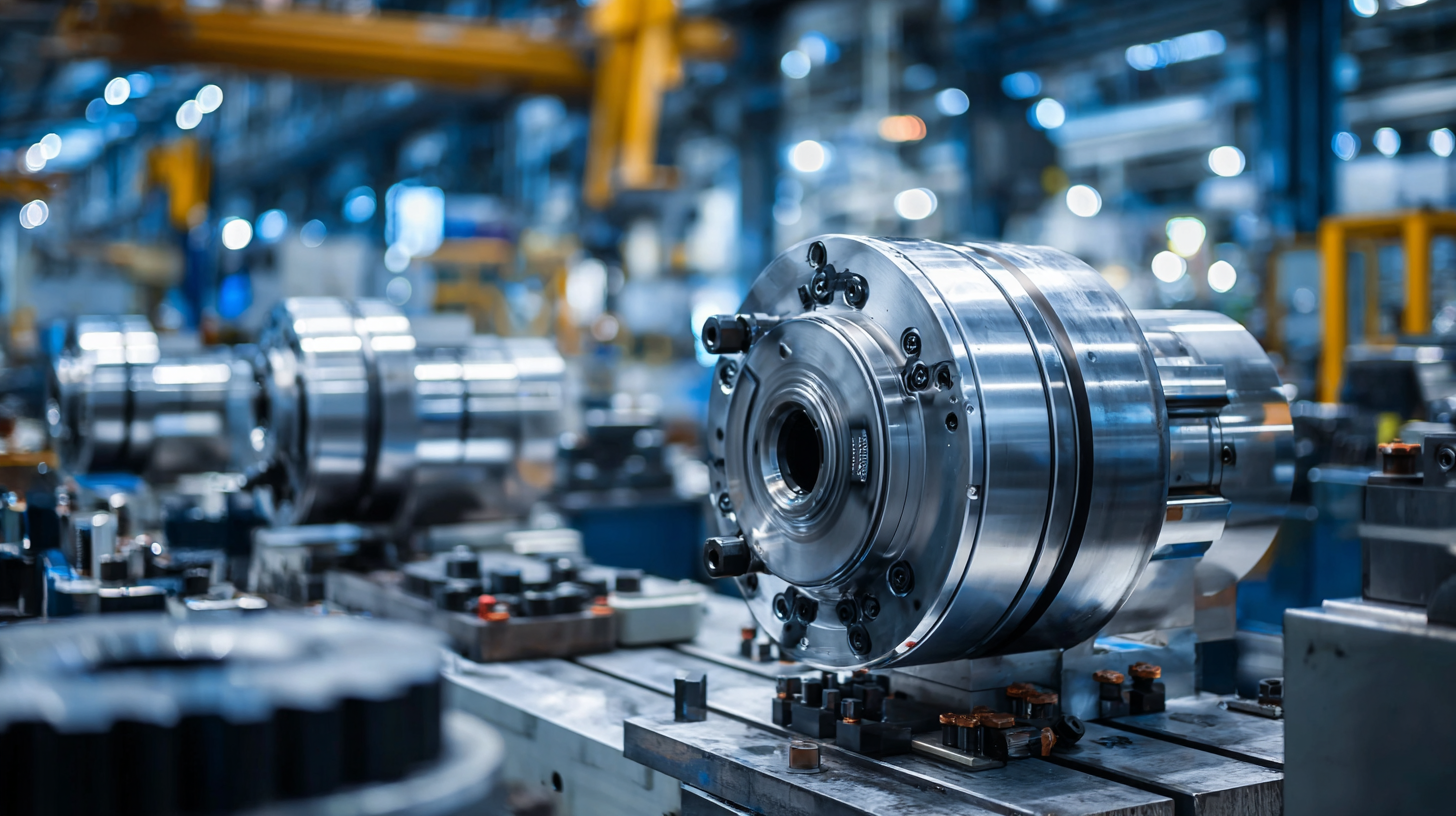

Predictive maintenance technologies are revolutionizing the manufacturing landscape by significantly cutting costs and reducing downtime. According to a report by McKinsey, implementing predictive maintenance can decrease maintenance costs by 20-25% while improving equipment uptime by 10-20%. By utilizing data analytics and IoT sensors, manufacturers can monitor machinery conditions in real-time, allowing them to anticipate failures before they occur. This proactive approach not only ensures smoother operations but also extends the lifespan of equipment, further enhancing industrial efficiency.

Recent studies indicate that industries adopting predictive maintenance strategies are achieving an impressive return on investment (ROI), often exceeding 30%. The need for machinery to remain operational is paramount; even a short period of downtime can result in lost production and revenue. For instance, a report from Deloitte estimates that unplanned downtime can cost manufacturers over $50 billion annually in the U.S. alone. By integrating predictive maintenance technologies, businesses are not only saving significant amounts on repair costs but are also fostering a more reliable and efficient manufacturing environment, ultimately leading to a competitive edge in the market.

The intersection of sustainability and automation is reshaping the landscape of industrial efficiency, as innovative energy-efficient machinery plays a pivotal role in modern manufacturing processes. As industries strive to reduce their carbon footprint, recent advancements in automation technology are not only enhancing productivity but also minimizing energy consumption. Machines equipped with smart sensors and AI algorithms enable real-time monitoring and optimization of energy use, allowing manufacturers to identify inefficiencies and adjust operations accordingly.

Moreover, developments in materials and design are enabling the creation of machinery that consumes less power while maintaining high performance. Innovations such as regenerative drives and energy recovery systems harness excess energy from operations, converting it into usable power for future tasks. By investing in these energy-efficient technologies, industries are not only adhering to stricter sustainability regulations but also reaping the benefits of lower operational costs and increased competitiveness in a rapidly evolving market. Ultimately, the fusion of sustainability and automation is a key driver of progress, paving the way for a more efficient and responsible industrial future.

The rise of the Industrial Internet of Things (IIoT) is revolutionizing how businesses approach operations efficiency. By leveraging real-time data analytics and connected devices, companies are now able to make informed decisions that enhance productivity and reduce downtime. According to a recent McKinsey report, organizations that implement IIoT can improve operational efficiency by up to 30%, leading to significant cost savings and improved resource management.

Integrating IIoT technologies allows for predictive maintenance and process optimization, which have become critical in today’s fast-paced industrial landscape. For example, manufacturers utilizing IIoT can reduce maintenance costs by 25% and decrease equipment failure rates by 70%, as reported by Boston Consulting Group. This data-driven decision-making empowers companies to pivot quickly in response to operational challenges, ensuring a nimble and responsive manufacturing process.

Tips: To maximize the benefits of IIoT in your operations, start by investing in robust data analytics tools that can process real-time insights. Additionally, create a cross-functional team that combines IT with operational expertise to identify key areas where automation can drive efficiency. Finally, prioritize employee training to ensure your workforce is equipped to work alongside advanced technologies.